While still an emerging technology, cargo sensors are already making an impact on businesses in the transportation and logistics industry. In our last post, we discussed how cargo sensors enable transportation companies to track and monitor the contents inside of a trailer in real-time from pick up to delivery, helping businesses to fully utilize their trailers, increase cargo security, improve operational efficiency, and make cost-saving decisions.

Since no two companies are the same, CloudHawk has designed its sensor technology to be modular so it can be deployed in a few different ways to fit any company’s needs and price points. Here are three common ways that cargo sensors can be configured to improve visibility and efficiency:

1) Multi-Sensor Trailer and Door Configuration

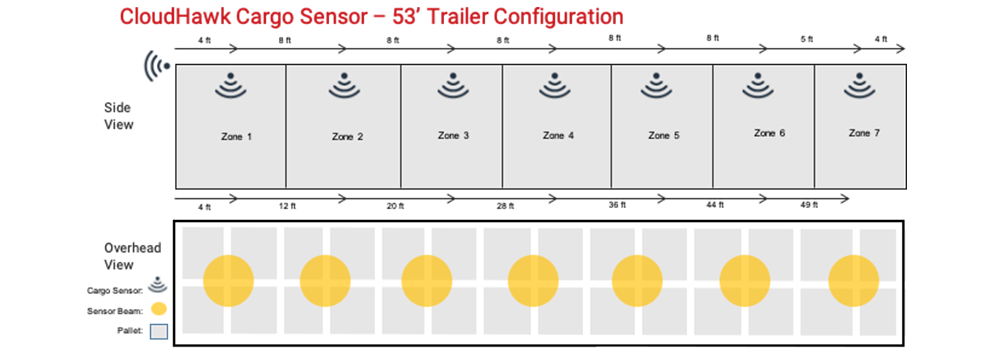

The multi-sensor trailer and door configuration enables fleet managers to monitor the entire length of a trailer from door to back, providing full visibility and actionable data. For transportation companies with different sized trailers, CloudHawk’s modular solution is ideal, as the number of sensors used can be customized to fit any trailer size.

For example, for a 53-foot trailer, seven sensors would typically be installed along the ceiling, splitting the trailer into seven zones. From the ceiling, the sensors scan downwards, measuring the distance to the floor. If the sensor detects an 8-foot distance to the floor, it knows that that zone is empty. On the other hand, if the trailer has been filled with cargo the sensor will detect the distance to the top of the cargo and calculate how much cargo has been loaded into each zone.

Cargo sensors can also monitor the percentage of available floor space in a zone by detecting the amount of space used by cargo in each zone and averaging the available amount. This information enables companies to make better decisions about scheduling and routing to optimize their trailer utilization and reduce empty drive miles. [The image below provides an example of how companies see the real-time cargo sensor data in the portal.]

Companies that select a multi-sensor solution often include a trailer door sensor to monitor door open/close status. This information provides valuable insight into load and unload times and helps mitigate cargo loss. When a trailer door opens, the sensors signal to the portal to switch the status to load, and the amount of time the doors are open is automatically monitored and recorded. When the door is shut, the sensors signal to the portal to change the load status. Management can use the data from the door sensors to understand how long the loading processes takes and identify any inefficiencies or unnecessary idle time. Together, door sensors and cargo sensors can also help management detect suspicious loading patterns, such as a trailer that appears full up to the door but actually is empty in the middle zones. Safety is also increased with the multi-sensor configuration as the sensors can detect when cargo has tilted or fallen, sending an automatic alert to the portal so users know to use caution when opening the trailer door.

2) Two-Sensor Configuration

Another way that businesses can deploy CloudHawk cargo sensors is a two-sensor configuration. In this situation, using a 53-foot trailer as an example, one sensor would be placed at the back of the trailer in zone seven and a second sensor would be placed by the door of the trailer in zone one. This configuration allows trucking companies to monitor whether or not the trailer is carrying any cargo, and it can also help detect whether the trailer is being fully utilized.

Being at the back of the trailer, zone seven is generally loaded first, so having a sensor in this area helps companies quickly determine whether cargo has been loaded or if the trailer is empty. If cargo is detected in zone seven then the sensor will report that the trailer contains cargo, but unlike with the multi-sensor configuration, the total cargo amount will be unknown.

A second sensor placed in zone one, by the trailer door, helps companies determine if there is room to fit more cargo. Since zone one is generally the last zone to be filled with cargo, companies can confidently assume that that the trailer is full if the sensor detects cargo in this zone. If the sensor does not detect anything in zone one, companies know that there is space for more cargo.

For companies with smaller trailers or limited budgets, the two-sensor configuration is a great alternative to the multi-sensor configuration, as it still provides visibility inside the trailer and enables informed decisions to be made. From here, companies can decide if this configuration satisfies their needs or if they would like to fill the gaps between zone one and zone seven to have full visibility of the trailer.

3) Single Sensor Configuration

The third way that businesses in the transportation sector are deploying CloudHawk cargo sensors is a single sensor configuration. This deployment style is commonly used by companies who are trying out an IoT solution for the first time or those that have budget restrictions but are still looking for some visibility inside their trailers. A single sensor configuration lets businesses know if their trailer is fully utilized or if there is still room for more cargo. In this configuration, the sensor is placed next to the trailer door in zone one to detect whether or not there is room in zone one for more cargo. This can also act as a door sensor, as CloudHawk sensors are often multi-tasking. For example, if the trailer has a roll-up door, the sensor on the ceiling will be covered when the door is open. The sensor will know that the door is open due to the perfect height that the door rolls up to each time. So, when the door rolls up and the sensor detects that there is an object three inches away it will tell the system that the door is open.

For businesses in the transportation sector, cargo sensors are a great tool to provide data on cargo height, cubic volume utilization, unused space and more. With CloudHawk’s modular technology, companies have the flexibility to add any number of sensors to meet their specific use case needs/ price point, as well as the flexibility to install the number of hardware devices needed to fit their trailer lengths.

For additional information on the benefits that CloudHawk cargo sensors provide, check out our What are Cargo Sensors blog!